|

|

PDF ATS660LSB Data sheet ( Hoja de datos )

| Número de pieza | ATS660LSB | |

| Descripción | TRUE ZERO-SPEED/ HALL-EFFECT ADAPTIVE GEAR-TOOTH SENSOR | |

| Fabricantes | Allegro MicroSystems | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de ATS660LSB (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

ATS660LSB

Some restrictions may apply to cer-

tain types of sales. Contact factory

for details.

TRUE ZERO-SPEED, HALL-EFFECT

ADAPTIVE GEAR-TOOTH SENSOR

1

2

3

4

Pin 1 = Supply

Pin 2 = Output

Pin 3 = Internal Connection

Pin 4 = Ground

Dwg. AH-006-4

PRELIMINARY INFORMATION

(subject to change without notice)

October 20, 2000

ABSOLUTE MAXIMUM RATINGS

at TA = 25°C

Supply Voltage, VCC ........................ 26.5 V*

Reverse Supply Voltage, VRCC ............ -24 V

Output OFF Voltage, VOUT ................. 26.5 V

Reverse Output Voltage, VROUT .......... -24 V

Continuous Output Current, IOUT ....... 20 mA

Reverse Output Current, IROUT .......... 50 mA

Package Power Dissipation,

PD .......................................... See Graph

Operating Temperature Range,

TA ............................. -40°C to +150°C*

Junction Temperature,

(continuous), TJ .......................... +165°C

(100 hr), TJM ............................... +180°C

Storage Temperature, TS ................... +170°C

* Operation at increased supply voltages with

external circuitry is described in Applications

Information. Devices for operation at in-

creased temperatures are available on special

order.

The ATS660LSB is an ideal gear-tooth sensor solution for uniform

teeth targets as found in today’s demanding transmission applications.

This digital differential Hall-effect sensor is the choice when repeatabil-

ity and timing accuracy count. The ATS660LSB incorporates patented

self-calibration circuitry (U.S. Pat. 5,917,320) that nulls out the effects

of installation air gap, ambient temperature, and magnet offsets to

provide superior timing accuracy with symmetrical targets over large

operating air gaps — typical of targets used in speed-sensing applica-

tions (pitches varying from below 0.5 to over 1.2 teeth per diametric

millimeter). The self-calibration at power up keeps the performance

optimized over the life of the sensor. The ATS660LSB has an open-

collector output for direct digital interfacing with no further signal

processing required. This device is available in a small 9-mm diameter

by 7-mm long package for optimal manufacturing.

The integrated circuit incorporates a dual-element Hall-effect

sensor and signal processing that switches in response to differential

magnetic signals created by the ferrous gear teeth. The circuitry

contains a sophisticated digital circuit to eliminate magnet and system

offsets and to achieve true zero-speed operation . D-to-A converters are

used to adjust the device gain at power on and to allow air-gap indepen-

dent switching, which greatly reduces vibration sensitivity of the

device.

FEATURES AND BENEFITS

I Fully optimized differential digital gear-tooth sensor

I Single-chip sensing IC for high reliability

I High vibration immunity

I Precise duty cycle

I Small mechanical size (9 mm diameter x 7 mm length)

I Automatic gain control circuitry (self calibration)

I True zero-speed operation

I Under-voltage lockout

I Wide operating temperature range

I Optimized Hall IC magnetic circuit

I Digital signal processing

I Large operating air gap range

I Wide operating voltage range

I Excellent repeatability performance

I Defined power-on state

Always order by complete part number: ATS660LSB .

1 page

ATS660LSB

TRUE ZERO-SPEED,

HALL-EFFECT ADAPTIVE

GEAR-TOOTH SENSOR

TYPICAL CHARACTERISTICS

12 12

10 10

8.0 8.0

6.0 6.0

4.0

2.0

0

0

B > BOP

TA = 150°C

TA = +25°C

TA = -40°C

5 10 15 20

SUPPLY VOLTAGE IN VOLTS

25 30

Dwg. GH-041-4

4.0

2.0

0

0

B < BRP

TA = 150°C

TA = +25°C

TA = -40°C

5 10 15 20

SUPPLY VOLTAGE IN VOLTS

25 30

Dwg. GH-041-3

1.2

1.0

TA = 150°C

TA = +25°C

TA = -40°C

0.8

0.6

0.4

0.2

0

-30 -25 -20 -15 -10 -5.0

0

REVERSE SUPPLY VOLTAGE IN VOLTS

Dwg. GH-031-2

350

300

250

200

150

100

50

0

0

B > BOP

TA = 150°C

TA = +25°C

TA = -40°C

5.0 10 15 20 25

OUTPUT SINK CURRENT IN mA

Dwg. GH-059-1

www.allegromicro.com

5

5 Page

ATS660LSB

TRUE ZERO-SPEED,

HALL-EFFECT ADAPTIVE

GEAR-TOOTH SENSOR

APPLICATIONS INFORMATION — Continued

Recommended evaluation technique. The self-

calibrating feature of the ATS660LSB requires that a

special evaluation technique be used to measure its high-

accuracy performance capabilities. Installation inaccura-

cies are calibrated out at power on; hence, it is extremely

important that the device be repowered at each air gap

when gathering duty cycle data.

The ATS660LSB is designed to minimize performance

variation (caused by the large air-gap variations resulting

from installation) by self-calibrating at power-on. These

functions should be tested using the procedures described

below.

Duty cycle capabilities after correct self-calibration can

be measured as follows:

1. Set the air gap to the desired value.

2. Power down and then power up the device.

3. Rotate the gear at the desired speed.

4. Wait for calibration to complete (64 output pulses to

occur).

5. Monitor output for correct switching and measure

accuracy.

6. Repeat the above for multiple air gaps within the

operating range of the device.

7. This can be repeated over the entire operating tem-

perature range.

There is an internal update algorithm that will maintain

the correct duty cycle as air gap changes with temperature.

Large changes in air gap will require the part to be reset

(by cycling power) to maintain the correct duty cycle.

Measurement of the effect of changing air gap after

power up:

1. Set the air gap to the desired value (nominal, for

example). Rotate the gear at the desired speed. Apply

power to the subassembly. Wait for 64 output pulses to

occur. Monitor output for correct switching and measure

accuracy.

2. Change the air gap by ±0.25 mm. Do not re-power the

subassembly. Wait for update algorithm to finish adjust-

ing thresholds, typically 1 to 2 rotations on a 60-tooth gear.

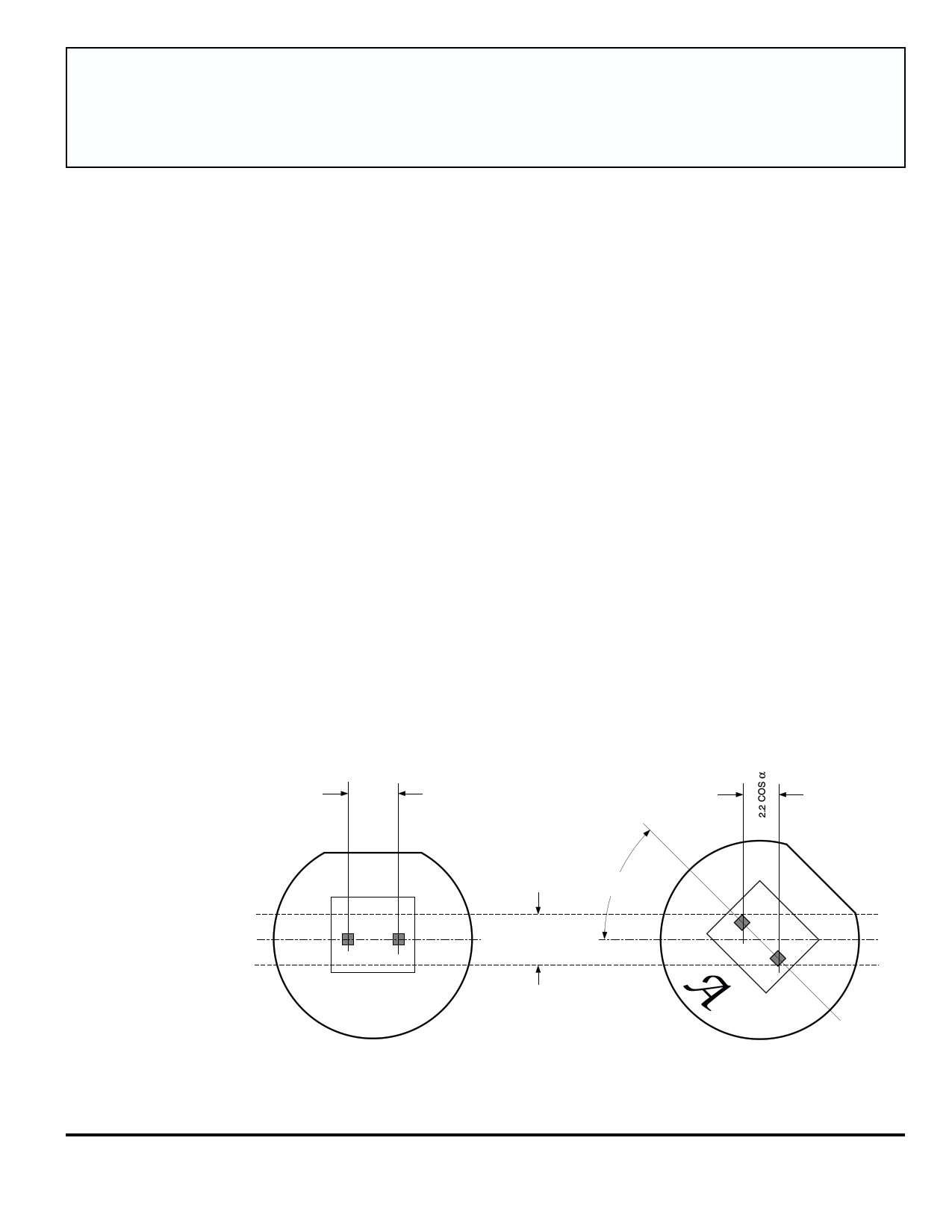

Operation with fine-pitch gears. For targets with a

circular pitch of less than 4 mm, a performance improve-

ment can be observed by rotating the front face of the

sensor subassembly. This sensor rotation decreases the

effective sensor-to-sensor spacing and increases the

capability of detecting fine tooth or valley configurations,

provided that the Hall elements are not rotated beyond the

width of the target.

2.2

Allegro

www.allegromicro.com

A

α

TARGET FACE WIDTH, F

>2.2 SIN α

Dwg. MH-018-5 mm

11

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet ATS660LSB.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ATS660LSB | TRUE ZERO-SPEED/ HALL-EFFECT ADAPTIVE GEAR-TOOTH SENSOR | Allegro MicroSystems |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |