|

|

PDF 74AHC1GU04 Data sheet ( Hoja de datos )

| Número de pieza | 74AHC1GU04 | |

| Descripción | Inverter | |

| Fabricantes | NXP Semiconductors | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de 74AHC1GU04 (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

INTEGRATED CIRCUITS

DATA SHEET

74AHC1GU04

Inverter

Product specification

File under Integrated Circuits, IC06

1999 May 19

1 page

Philips Semiconductors

Inverter

Product specification

74AHC1GU04

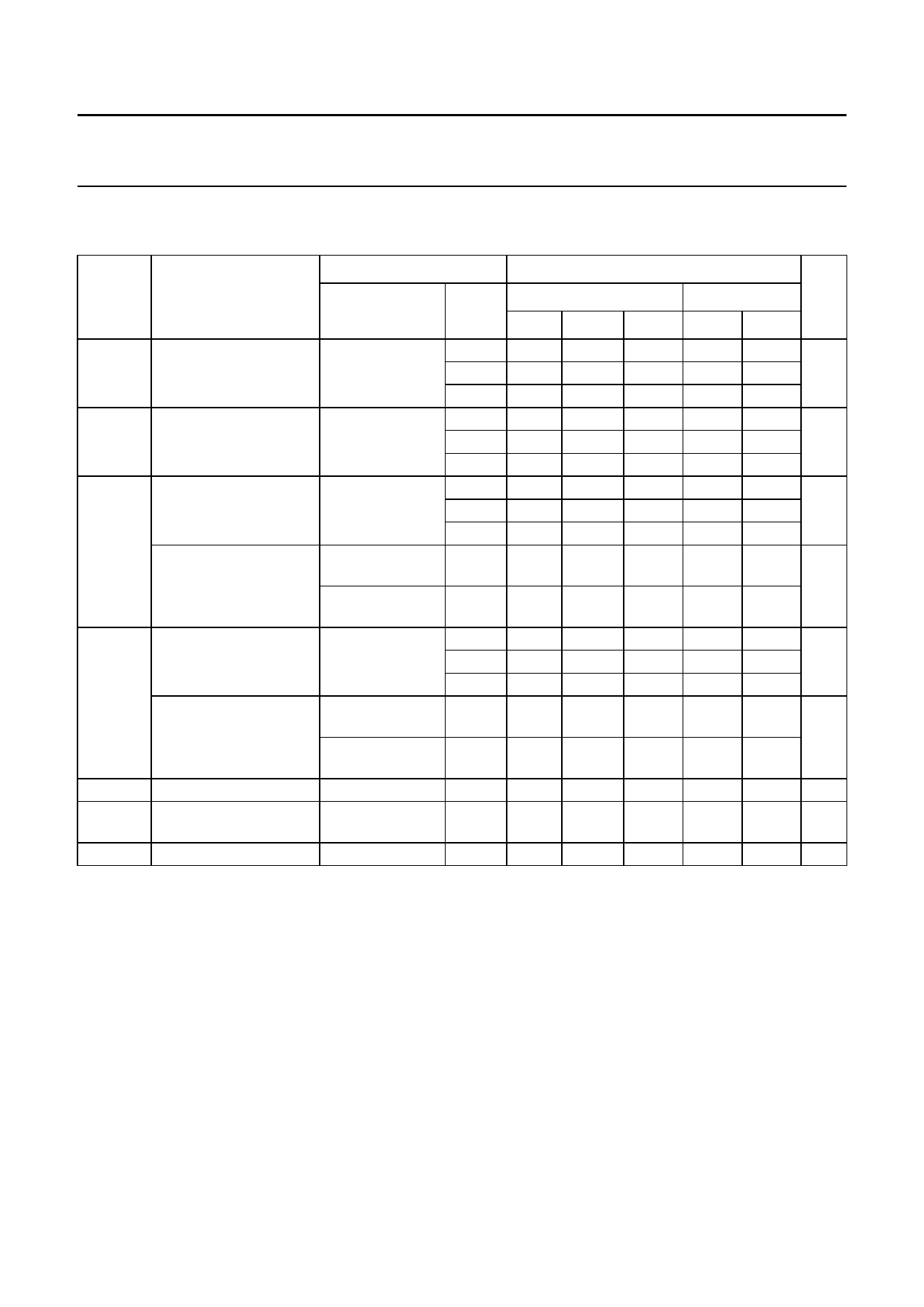

DC CHARACTERISTICS

Over recommended operating conditions; voltage are referenced to GND (ground = 0 V).

TEST CONDITIONS

SYMBOL

PARAMETER

OTHER

VCC (V)

MIN.

VIH HIGH-level input

voltage

2.0 1.7

3.0 2.4

5.5 4.4

VIL LOW-level input voltage

2.0 −

3.0 −

5.5 −

VOH HIGH-level output

VI = VIH or VIL; 2.0

1.9

voltage; all outputs

IO = −50 µA

3.0 2.9

4.5 4.4

HIGH-level output

voltage

VI = VIH or VIL;

IO = −4.0 mA

3.0

2.58

VI = VIH or VIL;

IO = −8.0 mA

4.5

3.94

VOL LOW-level output

VI = VIH or VIL; 2.0

−

voltage; all outputs

IO = 50 µA

3.0 −

4.5 −

LOW-level output

voltage

VI = VIH or VIL;

IO = 4 mA

3.0

−

VI = VIH or VIL;

IO = 8 mA

4.5

−

II

input leakage current VI = VCC or GND 5.5

−

ICC quiescent supply

current

VI = VCC or GND; 5.5

IO = 0

−

CI input capacitance

−

+25

TYP.

−

−

−

−

−

−

2.0

3.0

4.5

−

−

0

0

0

−

−

−

−

3

Tamb (°C)

−40 to +85

MAX.

−

−

−

0.3

0.6

1.1

−

−

−

−

MIN.

1.7

2.4

4.4

−

−

−

1.9

2.9

4.4

2.48

MAX.

−

−

−

0.3

0.6

1.1

−

−

−

−

− 3.8 −

0.1 −

0.1 −

0.1 −

0.36 −

0.1

0.1

0.1

0.44

0.36 −

0.44

0.1 −

1.0 −

1.0

10

− − 10

UNIT

V

V

V

V

V

V

µA

µA

pF

1999 May 19

5

5 Page

Philips Semiconductors

Inverter

Product specification

74AHC1GU04

SOLDERING

Introduction to soldering surface mount packages

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our “Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering is not always suitable

for surface mount ICs, or for printed-circuit boards with

high population densities. In these situations reflow

soldering is often used.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

Wave soldering

Conventional single wave soldering is not recommended

for surface mount devices (SMDs) or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• For packages with leads on four sides, the footprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

1999 May 19

11

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet 74AHC1GU04.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| 74AHC1GU04 | Inverter | NXP Semiconductors |

| 74AHC1GU04 | UNBUFFERED SINGLE INVERTER GATE | Diodes |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |