|

|

PDF FR-V520-xx-NA Data sheet ( Hoja de datos )

| Número de pieza | FR-V520-xx-NA | |

| Descripción | Variable Frequency Drives | |

| Fabricantes | Mitsubishi | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de FR-V520-xx-NA (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

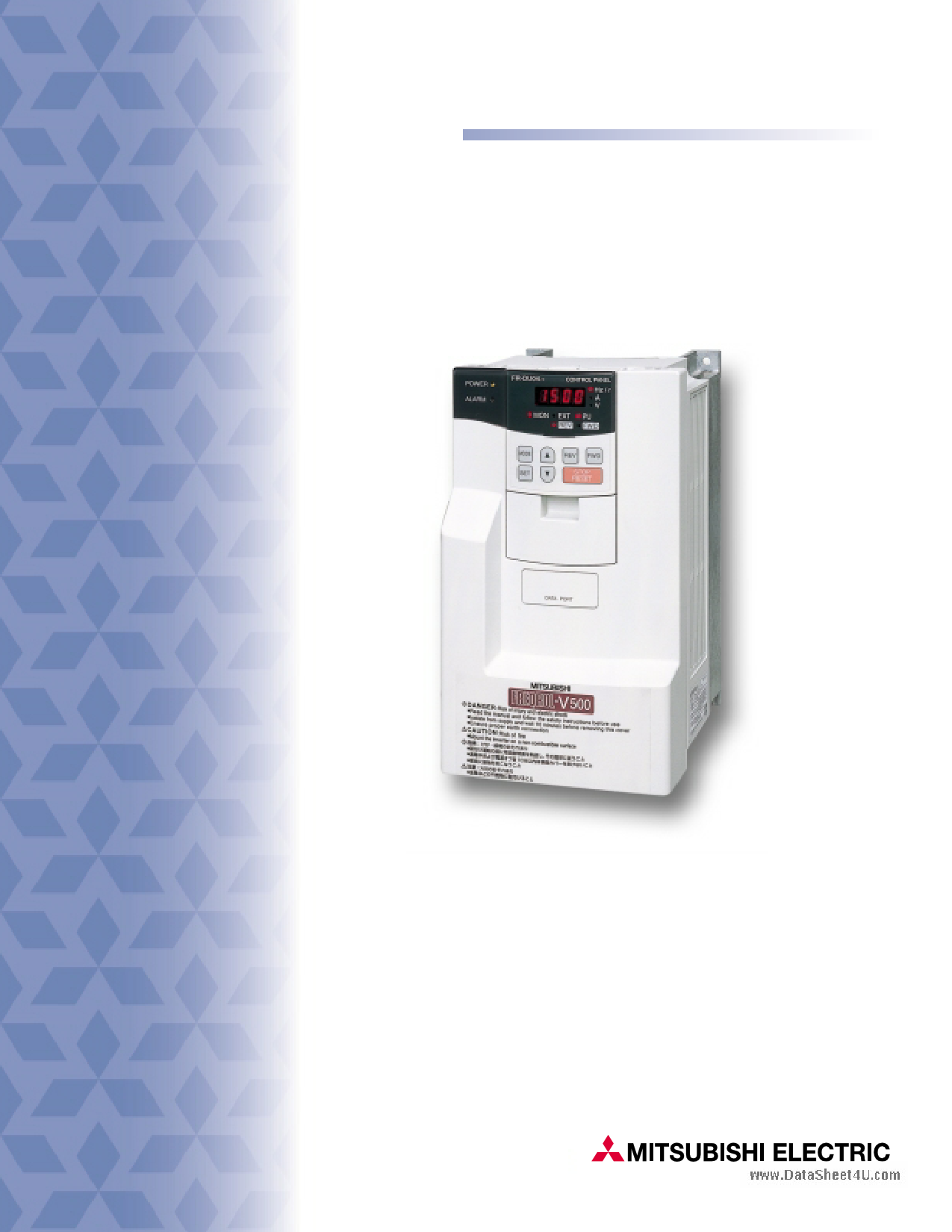

V500 Series

VARIABLE FREQUENCY DRIVES

1 – 400 HP

The Reliable “V”

Combining High Performance

with Ease-of-Use!

1 page

Environmental Conformance

Global Compliance

q Soft-PWM control reduces the motor’s metallic

sound at low carrier frequency. RFI noise is

lower compared to high carrier frequency.

q The compact and lightweight DC reactor (DCL)

can be connected to all capacities.

q European EMC Directives are easily met with

the optional EMC filter.

q Compatible with 240V / 480V power supply as

standard

q Input / output terminal logic (sink /source)

selectable

q Optional parameter unit (FR-PU04V) compatible

with eight languages

Compatible languages: English, Japanese, German,

French, Spanish, Italian, Swedish, Finnish

www.DataSheet4U.com

Standard Specifications

Model FR-V520-""-NA

Horsepower Rating

Rated Current (A)

Overload Current Rating (Note 1)

Regenerative Braking

Torque

Max. / Time

Tolerable

Work Rate

Rated Input, AC Voltage and Frequency

Tolerable AC Voltage Fluctuation

Tolerable Frequency Fluctuation

Supply (kVA) (Note 2)

Protective Structure

Cooling Method

Approximate Weight (lbs.)

1.5K 2.2K 3.7K 5.5K 7.5K

11K

15K 18.5K 22K

30K 37K

45K

2 3 5 7.5 10 15 20 25 30 40 50 60

9.0 13.0 20.0 28.5 37.5 54.0 72.8 88.0 103.5 126.5 168.0 198.0

150% for 60 sec., 200% for 0.5 sec. (inverse time characteristics)

100% 5 sec.

20% (Note 4)

3%ED (Note 4)

2% ED (Note 4)

Continuous (Note 4)

3-phase 200-240V 60Hz

3-phase 200-230V 60Hz

170-242V 50Hz, 170-264V 60Hz

170-242V 50Hz, 170-253V 60Hz

+/- 5%

5.0 6.5 10 14 19 23

33 39 48 57 77 90

Fully enclosed type (IP20, NEMA 1) (Note 3)

Open type (IP00)

Forced air cooling

7.7 7.7 13.2 13.2 13.2 30.8 30.8 46.2 66

88 88

121

55K

75

264.0

123

128

Model FR-V540-""-NA

Horsepower Rating

Rated Current (A)

Overload Current Rating (Note 1)

Regenerative Braking

Torque

Max. / Time

Tolerable

Work Rate

Rated Input, AC Voltage and Frequency

Tolerable AC Voltage Fluctuation

Tolerable Frequency Fluctuation

Supply (kVA) (Note 2)

Protective Structure

Cooling Method

Approximate Weight (lbs.)

1.5K 2.2K 3.7K 5.5K 7.5K

11K

15K 18.5K 22K

30K 37K

2 3 5 7.5 10 15 20 25 30 40 50

4.5 6.5 10.0 14.5 18.5 27.5 35.5 44.0 51.8 67.0 86.0

150% for 60 sec., 200% for 0.5 sec. (inverse time characteristics)

100% 5 sec.

20% (Note 4)

45K 55K

60 75

99.0 132.0

2% ED (Note 4)

Continuous (Note 4)

3-phase 380-480V 50Hz / 60Hz

323-528V 50Hz / 60Hz

+/- 5%

5.0 6.5 10.2 14 19 23 33 39 48 57 77 90 123

Fully enclosed type (IP20, NEMA 1) (Note 3)

Open type (IP00)

Forced air cooling

7.7 7.7 13.2 13.2 30.8 30.8 30.8 30.8 66

77 77

79 143

Model FR-V540L-""-NA

Horsepower Rating

Rated Current (A)

Rated Capacity (kVA)

Overload Current Rating (Note 1)

Regenerative Braking

Torque

Max. / Time

Tolerable

Work Rate

Rated Input, AC Voltage and Frequency

Tolerable AC Voltage Fluctuation

Tolerable Frequency Fluctuation

Protective Structure (JEM1030)

Cooling Method

Approximate Inverter Weight (lbs.)

Approximate DC Reactor Weight (lbs.)

75K

100-125

165

114

165

49

90K

125-150

195

135

165

49

110K

132K

160K

150-200

200

250

240 270 330

166 187 229

150% for 60 sec., 200% for 0.5 sec. (inverse time characteristics)

20%

Continuous

3-phase 380-480V 50Hz / 60Hz

323-528V 50Hz / 60Hz

+/- 5%

Open type (IP00)

Forced air cooling

265 265 485

79 79 106

200K

300-350

415

288

518

126

Notes:

1. The overload current rating percentage indicates the percentage with respect to the inverter’s rated output current. When used repeatedly, it is necessary to wait for the

inverter and motor to return to less than the temperature at 100% load.

2. The power capacity will change according to the power supply side impedance (including the input reactor and power) value.

3. When the wiring cover for options is removed and built-in options are mounted, the protective structure will be open chassis (IP00).

4. With the 1.5kW to 15kW capacities, 100% torque 10% ED can be achieved by connecting the dedicated external brake resistor (FR-ABR) option.

250K

400

505

350

518

126

4

5 Page

Options

Name

Expanded Input Thermistor Interface

Expanded Output Pulse Division Output

Position Control

Machine Orientation

Trace Card

16-bit Digital Input

www.DataSheet4U.com

SSCNET

Ethernet

12-bit Digital Input

Digital Output

Expanded Analog Output

Relay Output

Orientation

Pulse Train Input

Computer Link

Relay Output

Profibus DP

DeviceNet TM

CC-Link

Modbus Plus

Parameter Unit (8-language)

Parameter Unit Connection Cable

Heat Sink Protrusion Attachment

Totally Enclosed Structure Attachment

Wire Conduit Connection Attachment

Installation Adaptor

EMC Directive Compatible Noise Filter

High-frequency Braking Resistor

Power Factor Improving DC Reactor

Power Factor Improving AC Reactor

Radio Noise Filter

Line Noise Filter

BU Type Brake Unit

Brake Unit

Resistor Unit

Regenerative Common Converter

Standalone Reactor Dedicated for FR-CV

High-power Factor Converter

Type

FR-V5AX

FR-V5AY

FR-V5AP

FR-V5AM

T-TRC50

FR-V5AH

FR-V5NS

FR-V5NE

FR-A5AX

FR-A5AY

FR-A5AR

FR-A5AP

FR-A5NR

FR-A5NPA

FR-A5ND

FR-A5NC

FR-A5NM

FR-PU04V

FR-CB2 "" (Note 2)

FR-A5CN "" (Note 2)

FR-A5CV "" (Note 2)

FR-A5FN "" (Note 2)

FR-A5AT "" (Note 2)

SF "" (Note 2)

FR-ABR "" (Note 1)

FR-BEL"" (Note 1)

FR-BAL "" (Note 1)

FR-BIF "" (Note 1)

FR-BSF01

FR-BLF

BU-1500~15K

FR-BU-15K to 55K

FR-BR-15K to 55K

FR-CV-7.5K(-AT)

to 55K (Note 5)

FR-CVL-7.5K to 55K

FR-HC-7.5K to 55K

Details

• Any six out of 25 types of input signals can be selected and contact input.

• Highly accurate operation is possible by using the high resolution analog input (16-bit).

• When using the motor with thermistor, the motor temperature can be detected by the

thermistor, and the generated torque’s temperature fluctuation reduced.

• Three out of 37 types of output signals are selected and open collector output to the inverter.

• The pulse train input by the inverter can be divided and output.

• By inputting a pulse train from an external source, positioning can be controlled.

The Mitsubishi PLC (positioning unit) can also be connected.

• By using in combination with the position detector (PLG) installed on the machine's

spindle, the spindle can be stopped at a set position (orientation function).

• By mounting this card on the inverter, the various data (output current, etc.) sampled

can be saved in the memory.

• This is an input interface used to set the inverter speed with a high accuracy using a

4-digit BCD or 16-bit binary code signal from an external source.

• The inverter can be controlled via the Q Series Motion Control CPU or QD-75M.

• All operations from inverter startup to maintenance are supported.

• This is an input interface used to set the inverter speed with a high accuracy using

a 3-digit BCD or 12-bit binary code signal from an external source.

• The gain and offset can also be adjusted.

• Seven out of 37 types of output signals provided as a standard in the inverter

can be randomly selected and output from the open collector.

• 18 types of signals, such as rotation speed, output voltage and output current,

which can be monitored with terminals DA1 and DA2 are expanded and output.

• A 20mADC or 5VDC (10V) meter can be connected.

• Three out of 37 types of output signals provided as a standard in the inverter

can be randomly selected and output from the relay contact.

• By using in combination with the position detector (PLG) installed on the

machine's spindle, the spindle can be stopped at a set position (orientation function).

• The speed command to the inverter can be input as pulse train signals.

• When connected with a computer such as a personal computer or FA controller

by a communication cable, the inverter can be operated and monitored and

the parameters can be changed with user programs in the computer.

• One of the output signals provided as a standard in the inverter can be randomly

selected and output as a relay contact.

• The inverter can be operated and monitored and the parameters can be changed

from a computer or PLC.

Interactive parameter unit with LCD display (Compatible with English, Japanese,

German, French, Spanish, Italian, Swedish and Finnish)

Cable for connecting operation panel and parameter unit

The inverter heat sink section can be protruded from the back of the control panel.

This enables compliance with the totally enclosed structure specifications (IP40).

The wire conduit can be directly connected. This enables compliance to IP20.

Attachment for installing on the V500 Series using the V200 installation holes.

Noise filter compatible with EMC Directives (EN50071-2)

Used for improving braking performance of brakes built into inverter

Used for improving inverter input power factor (total power factor approx. 95%)

and for balancing power supply

Used for improving inverter input power factor (total power factor approx. 95%)

and for balancing power supply

Used to reduce radio noise

Used to reduce line noise (applicable for 3.7kW or smaller capacities)

Used to reduce line noise

Used for improving inverter braking performance (for high inertia loads or negative loads)

Use the brake unit and resistor unit as a set

Used for improving inverter braking performance (for high inertia loads or negative loads)

High-function unit that regenerates the braking energy generated at the

motor into power with a common converter method.

Power balancing reactor for FR-CV

The high-power factor converter allows the converter section to alter the input

current waveform into a sine wave and greatly reduce the higher harmonics.

(used in combination with the standard accessories.)

Applicable

Inverter

Common for all

models

Common for all

models

Compatible with 1.5 to 55k capacities

Compatible with 1.5 to 15k capacities

Compatible with 18.5 to 55k capacities

Compatible with 1.5 to 7.5k,

15k capacities

Compatible with 1.5 to 55k capacities

Compatible with 1.5 to 15k capacities

Compatible with 1.5 to 55k capacities

Compatible with 1.5 to 55k capacities

Common for all

models

Common for all

models

Notes:

1. "" indicates the capacity.

2. "" indicates the value.

3. Up to three built-in options can be mounted simultaneously. (Only one of the same options can be mounted. Only one communication option can be mounted.)

4. When the option wiring cover is removed and the built-in option is mounted, the structure will be the open type (IP00).

5. -AT indicates the inner panel installation dimensions. When not indicated, this is the heat sink protrusion type. The 37k and larger capacity can be installed in any orientation by changing the position of the

installation legs. There is no -AT.

10

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet FR-V520-xx-NA.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| FR-V520-xx-NA | Variable Frequency Drives | Mitsubishi |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |