|

|

PDF NCT218 Data sheet ( Hoja de datos )

| Número de pieza | NCT218 | |

| Descripción | High Accuracy Temperature Monitor | |

| Fabricantes | ON Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de NCT218 (archivo pdf) en la parte inferior de esta página. Total 18 Páginas | ||

|

No Preview Available !

NCT218

Low Voltage, High

Accuracy Temperature

Monitor with I2C Interface

The NCT218 is a dual−channel digital thermometer and

undertemperature/overtemperature alarm, intended for use in thermal

management systems requiring low power and size. The NCT218

operates over a supply range of 1.4 V to 2.75 V making it possible to

use it in a wide range of applications including low power devices.

The NCT218 can measure the temperature of a remote thermal diode

accurate to ±1°C and the ambient temperature accurate to ±1.75°C.

The device operates over a wide temperature range of −40°C to

+125°C.

The NCT218 includes series resistance cancellation, where up to

500 W (typical) of resistance in series with the temperature monitoring

diode can be automatically cancelled from the temperature result,

allowing noise filtering. The NCT218 has a configurable ALERT

output and overtemperature shutdown THERM pin.

Communication with the NCT218 is accomplished via the I2C

interface which is compatible with industry standard protocols.

Through this interface the NCT218s internal registers may be

accessed. These registers allow the user to read the current

temperature from both the local (ambient) and remote channels,

change the configuration settings and adjust each channels limits.

An ALERT output signals when the on−chip or remote temperatures

are out of range. The THERM output is a comparator output that can

be used to shut down the system if it exceeds the programmed limit.

The ALERT output can be reconfigured as a second THERM output, if

required.

Features

• Small DFN Package

• On−Chip and Remote Temperature Sensor

• Low Voltage Operation: 1.4 V to 2.75 V

• Low Quiescent Current:

♦ 44 mA Normal Mode (max)

♦ 20 mA Shutdown (max)

• Power Saving Shutdown Mode

• Operating Temperature Range of −40°C to 125°C

• Series Resistance Cancellation up to 500 W

• Low D− bias for Operation with Low Voltage Processors

• 2−wire I2C Serial Interface

• Programmable Over/Undertemperature Limits

• These are Pb−Free Devices

Applications

• Smart Phones, Tablet PCs, Satellite Navigation, Smart Batteries

© Semiconductor Components Industries, LLC, 2013

December, 2013 − Rev. 2

1

http://onsemi.com

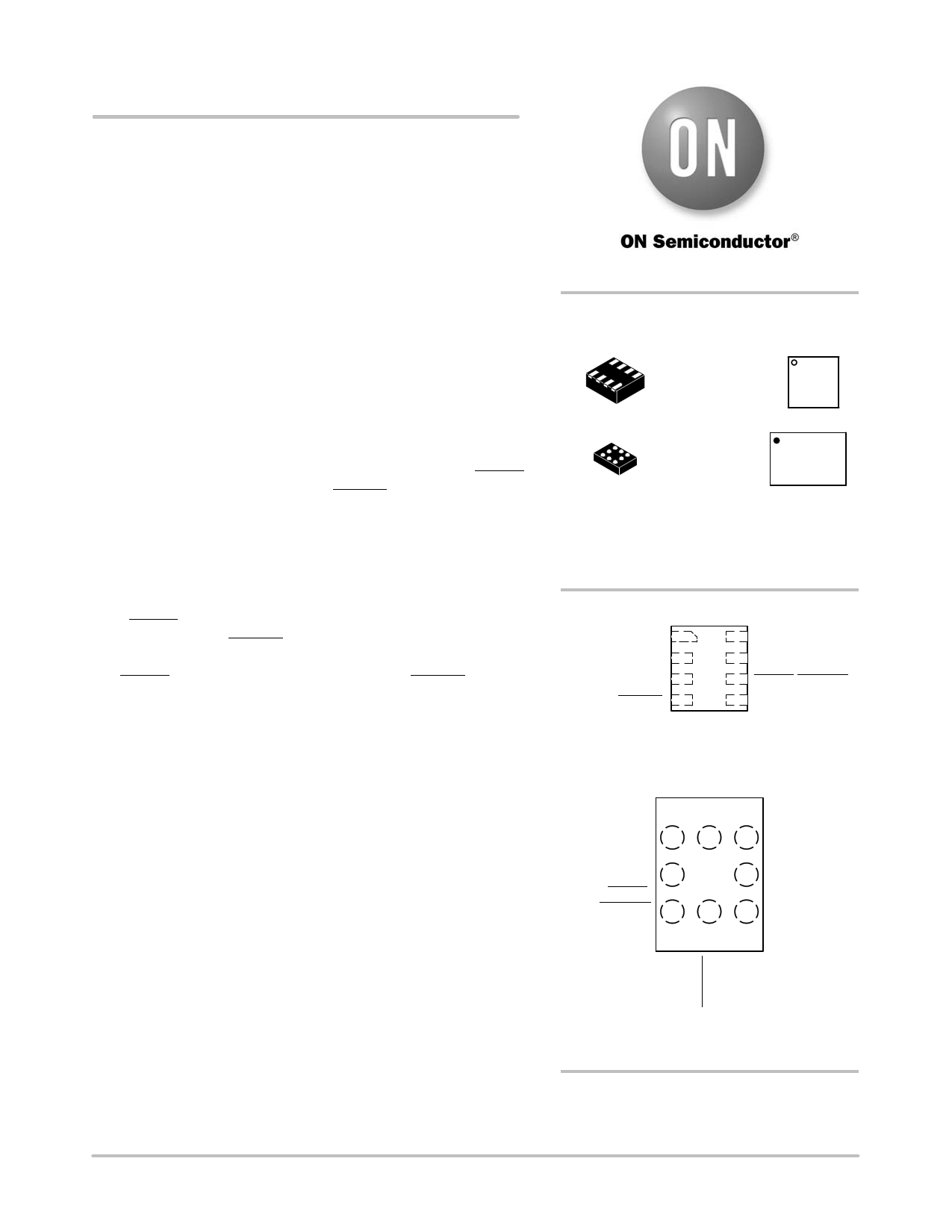

MARKING

DIAGRAMS

DFN8

MT SUFFIX

CASE 511BU

1

T2 MG

G

WLCSP8

CASE 567DH

NCT218

AYWW

M = Date Code

AY = Assembly year

WW = Work Week

G = Pb−Free Device

(Note: Microdot may be in either location)

PIN ASSIGNMENTS

VDD

D+

D−

THERM

18

27

36

45

DFN8

(Top View)

SCL

SDA

ALERT/THERM2

GND

SDA C1 B1 A1 VDD

GND C2

A2 D+

ALERT/

THERM2 C3 B3 A3 D−

WLCSP8

(Top View)

ORDERING INFORMATION

See detailed ordering and shipping information on page 16 of

this data sheet.

Publication Order Number:

NCT218/D

1 page

NCT218

Theory of Operation

The NCT218 is a local and remote temperature sensor and

over/under temperature alarm, with the added ability to

automatically cancel the effect of 500 W (typical) of

resistance in series with the temperature monitoring diode.

When the NCT218 is operating normally, the on−board

ADC operates in a free running mode. The analog input

multiplexer alternately selects either the on−chip

temperature sensor to measure its local temperature or the

remote temperature sensor. The ADC digitizes these signals

and the results are stored in the local and remote temperature

value registers.

The local and remote measurement results are compared

with the corresponding high, low, and THERM temperature

limits, stored in eight on−chip registers. Out−of−limit

comparisons generate flags that are stored in the status

register. A result that exceeds the high temperature limit or

the low temperature limit causes the ALERT output to

assert. The ALERT output also asserts if an external diode

fault is detected. Exceeding the THERM temperature limits

causes the THERM output to assert low. The ALERT output

can be reprogrammed as a second THERM output.

The limit registers are programmed and the device

controlled and configured via the serial I2C. The contents of

any register are also read back via the I2C. Control and

configuration functions consist of switching the device

between normal operation and standby mode, selecting the

temperature measurement range, masking or enabling the

ALERT output, switching Pin 6 between ALERT and

THERM2, and selecting the conversion rate.

Series Resistance Cancellation

Parasitic resistance to the D+ and D− inputs to the

NCT218, seen in series with the remote diode, is caused by

a variety of factors, including PCB track resistance and track

length. This series resistance appears as a temperature ofset

in the remote sensor’s temperature measurement. This error

typically causes a 0.5°C offset per ohm of parasitic

resistance in series with the remote diode.

The NCT218 automatically cancels the effect of this

series resistance on the temperature reading, giving a more

accurate result, without the need for user characterization of

this resistance. The NCT218 is designed to automatically

cancel typically up to 150 W of resistance. By using an

advanced temperature measurement method, this process is

transparent to the user. This feature permits resistances to be

added to the sensor path to produce a filter, allowing the part

to be used in noisy environments. See the section on Noise

Filtering for more details.

Temperature Measurement Method

A simple method of measuring temperature is to exploit

the negative temperature coefficient of a diode, measuring

the base emitter voltage (VBE) of a transistor operated at

constant current. However, this technique requires

calibration to null the effect of the absolute value of VBE,

which varies from device to device.

The technique used in the NCT218 measures the change

in VBE when the device operates at three different currents.

Previous devices used only two operating currents, but it is

the use of a third current that allows automatic cancellation

of resistances in series with the external temperature sensor.

Figure 4 shows the input signal conditioning used to

measure the output of an external temperature sensor. This

figure shows the external sensor as a substrate transistor, but

it can equally be a discrete transistor. If a discrete transistor

is used, the collector is not grounded but is linked to the base.

To prevent ground noise interfering with the measurement,

the more negative terminal of the sensor is not referenced to

ground, but is biased above ground by an internal resistor at

the D− input. C1 may be added as a noise filter (a

recommended maximum value of 1000 pF). However, a

better option in noisy environments is to add a filter, as

described in the Noise Filtering section. See the Layout

Considerations section for more information on C1.

To measure DVBE, the operating current through the

sensor is switched among three related currents. As shown

in Figure 4, N1 x I and N2 x I are different multiples of the

current, I. The currents through the temperature diode are

switched between I and N1 x I, giving DVBE1; and then

between I and N2 x I, giving DVBE2. The temperature is then

calculated using the two DVBE measurements. This method

also cancels the effect of any series resistance on the

temperature measurement.

The resulting DVBE waveforms are passed through a

65 kHz low−pass filter to remove noise and then to a

chopper−stabilized amplifier. This amplifies and rectifies

the waveform to produce a dc voltage proportional to DVBE.

The ADC digitizes this voltage producing a temperature

measurement. To reduce the effects of noise, digital filtering

is performed by averaging the results of 16 measurement

cycles for low conversion rates. At rates of 16−, 32− and

64−conversions/second, no digital averaging occurs. Signal

conditioning and measurement of the internal temperature

sensor are performed in the same manner.

http://onsemi.com

5

5 Page

NCT218

SERIAL INTERFACE

Control of the NCT218 is carried out via the I2C

compatible serial interface. The NCT218 is connected to this

bus as a slave device, under the control of a master device.

The NCT218 has a bus timeout feature. When this is

enabled, the bus times out after typically 25 ms of no

activity. After this time, the NCT218 resets the SDA line

back to its idle state (high impedance) and waits for the next

start condition. However, this feature is not enabled by

default. Bit 7 of the consecutive alert register (Address =

0x22) should be set to enable it.

Addressing the Device

In general, every I2C device has a 7−bit device address,

except for some devices that have extended 10−bit

addresses. When the master device sends a device address

over the bus, the slave device with that address responds.

The NCT218 is available with one device address, 0x4C. An

NCT218 with address 0x4D is also available for systems

requiring more than one NCT218 devices.

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a

start condition, defined as a high to low transition

on the serial data line SDA, while the serial clock

line SCL remains high. This indicates that an

address/data stream is going to follow. All slave

peripherals connected to the serial bus respond to

the start condition and shift in the next eight bits,

consisting of a 7−bit address (MSB first) plus a

read/write (R/W) bit, which deternimes the

direction of the data transfer i.e. whether data is

written to, or read from, the slave device. The

peripheral with the address corresponding to the

transmitted address responds by pulling the data

line low during the low period before the ninth

clock pulse, known as the acknowledge bit. All

other devices on the bus now remain idle while the

selected device waits for data to be read from or

written to it. If the R/W bit is a zero then the

master writes to the slave device. If the R/W bit is

a one then the master reads from the slave device.

2. Data is sent over the serial bus in sequences of

nine clock pulses, eight bits of data followed by an

acknowledge bit from the receiver of data.

Transitions on the data line must occur during the

low period of the clock signal and remain stable

during the high period, since a low−to−high

transition when the clock is high can be interpreted

as a stop signal.

3. When all data bytes have been read or written,

stop conditions are established. In write mode, the

master pulls the data line high during the tenth

clock pulse to assert a stop condition. In read

mode, the master overrides the acknowledge bit by

pulling the data line high during the low period

before the ninth clock pulse. This is known as no

acknowledge. The master takes the data line low

during the low period before the tenth clock pulse,

then high during the tenth clock pulse to assert a

stop condition.

To write data to one of the device data registers, or to read

data from it, the address pointer register must be set so that

the correct data register is addressed. The first byte of a write

operation always contains a valid address that is stored in the

address pointer register. If data is to be written to the device,

the write operation contains a second data byte that is written

to the register selected by the address pointer register.

This procedure is illustrated in Figure 5. The device

address is sent over the bus followed by R/W set to 0. This

is followed by two data bytes. The first data byte is the

address of the internal data register to be written to, which

is stored in the address pointer register. The second data byte

is the data to be written to the internal data register.

When reading data from a register there are two

possibilities.

• If the address pointer register value of the NCT218 is

unknown or not the desired value, it is first necessary to

set it to the correct value before data can be read from

the desired data register. This is done by writing to the

NCT218 as before, but only the data byte containing

the register read address is sent, because data is not to

be written to the register see Figure 5.

A read operation is then performed consisting of the

serial bus address, R/W bit set to 1, followed by the

data byte read from the data register see Figure 7.

• If the address pointer register is known to be at the

desired address, data can be read from the

corresponding data register without first writing to the

address pointer register and the bus transaction shown

in Figure 6 can be omitted.

Notes:

• It is possible to read a data byte from a data register

without first writing to the address pointer register.

However, if the address pointer register is already at the

correct value, it is not possible to write data to a register

without writing to the address pointer register because

the first data byte of a write is always written to the

address pointer register.

• Some of the registers have different addresses for read

and write operations. The write address of a register

must be written to the address pointer if data is to be

written to that register, but it may not be possible to

read data from that address. The read address of a

register must be written to the address pointer before

data can be read from that register.

http://onsemi.com

11

11 Page | ||

| Páginas | Total 18 Páginas | |

| PDF Descargar | [ Datasheet NCT218.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| NCT210 | Low Cost Microprocessor System Temperature Monitor Microcomputer | ON Semiconductor |

| NCT214 | Temperature Monitor | ON Semiconductor |

| NCT218 | High Accuracy Temperature Monitor | ON Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |